8. Cut down PCB cost because need not making V-groove on PCB

PCB Depaneling Router, CW-F02 Specification:

| I. Hardware |

|

| System models / types | Windows XP Professional |

| Overall |

|

| FootPrint (LxWxH) | 800mm*850mm*1700mm |

| Weight (Approximate) | 150KG |

| Adjustable machine footings (for height) | 60~110mm |

| Manipulator |

|

| Manipulator Motor | Panasonic MINAS A5 series |

| Manipulator Repeatability | 0.001mm |

| Axis configuration |

|

| Maximum Axis Travel (X,Y,Z) | 400mm*650mm*50mm |

| Work station |

|

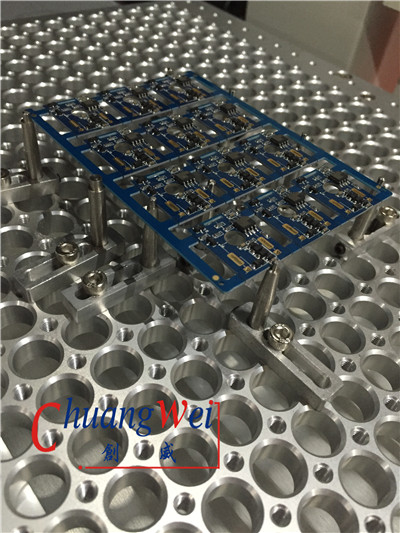

| Board Positioning | Fixture positioning, thimble universal positioning, vision correction |

| Loading/Unloading | manual |

| Routing Range | 320mm*320mm |

| Panel Thickness | 3mm |

| Fixturing |

|

| Rigid Fixturing | Universal thimble & anti-static fixture |

| Top Clamp | Using hole positioning |

| Spindle Motor |

|

| Power | 100W |

| Max. speed | 60000rpm/min |

| Cooling | Natural cooling and air-cooled |

| Router bit size | 3mm*3mm |

| Tool change | Use Special wrench |

| Routing capability |

|

|

|

|

| Max routing speed | 100mm/s |

| Repeatability | 0.02mm |

| Vacuum System |

|

| Power | 0.75KW220V Single-phase motor |

| Filtration | Vertical and horizontal |

| Utilities |

|

| Power | 1.5KW AC220V |

| Air supply | 4~5KG/cm2 |

| II. Software and Programming |

|

| System platform | Windows XP Professional (Service3,v.3244) |

| System Stability | 24 hours without exception |

| Vision system | Precision CCD vision alignment correction system (SONY 250 series) |

| Programming |

|

| On-line | Online Programming |

| Editing function | Straight, diagonal, circular arc, circle |

| No. of Programs that can be installed | select a storage location according to client's requirement |

| Configure CCD Camera for programming | Fangchen F130 High Precision CCD |

| Toolbit Diameter Compensation | Provide different angles to compensate for the user to choose different shapes |

| Filter Change Interval (distance) setting | automatic cleaning filter and dust to dust collection box when processing is completed centralized each time |

| Operation Monitors |

|

| 3-color Tower Light | 3-color light monitor the machine's working conditions |

| Tool Break Detection | Automatic detection of tool life & using time |

| Motor Overheat Detection | overheating, overload, low voltage protection function |

| Servo Overload Detection | Overload, the line is normal, low-voltage protection function |

| Tool Life Tracking | tool life time detection |

| PCB Board Counter | cutting item,cutting counting, diversified way of counting. |

| Vacuum Filter Change Alarm | not use to vacuum filter |

| Machine Error History | The software automatically records all alarms memory |

| III. Accuracy |

|

| Axis positioning accuracy | 0.01mm |

| Routing Accuracy | 0.02mm |

| IV. Safety |

|

| Enclosed Work Area | Using four seal protection |

| Door Interlock Sensors | micro-switch sensor |

| Emergency Stop Button | Yes |

Contact: Bunny

Phone: /Wechat/Whatapp: +86 136 8490 4990

Tel: 86-0769-82784046

Company: Dongguan Chuangwei Electronic Equipment Manufactory

Add: Building 2, Gang Hua Xing Industrial Park, Chongqing Road, Fuyong Town, Shenzhen, China 518103